You design in 3D, so why not inspect in 3D? Geomagic Qualify enables fast, accurate, easy-to-understand graphical comparisons between CAD models and as-built parts for first-article inspection, inline or shop-floor inspection, trend analysis, and in-depth assessment.

Inspect products in a fraction of the time

With Geomagic Qualify, inspection and approval can

be completed in hours instead of weeks accelerating

time to market, significantly reducing cost and

giving you a measurable competitive advantage

in the design and manufacturing process.

Obtain accurate, certified and tested results

Geomagic Qualify is certified by the PTB (Physikalisch-

Technische Bundesanstalt) and meets the strict quality

standards established by leading manufacturers like

Fiat, General Motors, Honeywell and Pratt & Whitney.

Improve design efficiency

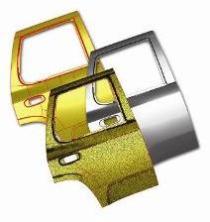

An intuitive user interface guides you through the entire

align, compare, evaluate and report workflow. Graphical

comparisons of “as designed” vs. “as manufactured”

information aids the designer’s understanding of problems,

enabling quicker turnaround time for design changes.

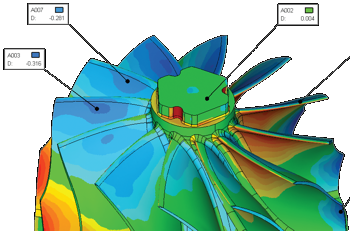

Sustain manufacturing quality in real time

Maintain quality control for in-line production and shopfloor

inspection. Trend analysis enables statistical process

control (SPC) on multiple samples, providing insights into

deviation trends. Deviation color maps allow users to instantly

identify problem areas that can be further analyzed.

With Geomagic Qualify, inspection and approval can

be completed in hours instead of weeks accelerating

time to market, significantly reducing cost and

giving you a measurable competitive advantage

in the design and manufacturing process.

Obtain accurate, certified and tested results

Geomagic Qualify is certified by the PTB (Physikalisch-

Technische Bundesanstalt) and meets the strict quality

standards established by leading manufacturers like

Fiat, General Motors, Honeywell and Pratt & Whitney.

Improve design efficiency

An intuitive user interface guides you through the entire

align, compare, evaluate and report workflow. Graphical

comparisons of “as designed” vs. “as manufactured”

information aids the designer’s understanding of problems,

enabling quicker turnaround time for design changes.

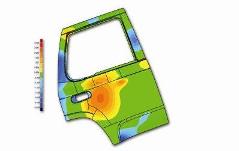

Sustain manufacturing quality in real time

Maintain quality control for in-line production and shopfloor

inspection. Trend analysis enables statistical process

control (SPC) on multiple samples, providing insights into

deviation trends. Deviation color maps allow users to instantly

identify problem areas that can be further analyzed.

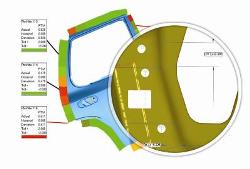

Take advantage of Geomagic Qualify’s sophisticated

analysis features including wall thickness, gap and

flush, edge comparison, geometric dimensioning &

tolerancing (GD&T), as well as 2D and 3D dimensioning.

Quickly assess out-of-tolerance conditions to enable

immediate correction to the manufacturing process.

Maximize inspection coverage

For multi-sensor metrology users who want to take advantage

of the combined strengths of 3D scanners and hard

probes, Geomagic Qualify streamlines workflow, improves

alignment accuracy, and provides comprehensive inspection

coverage. A single interface enables users to quickly capture

a full 3D scan of the object and then use a hard probe to

measure hard to reach areas, increase alignment accuracy

or verify measurements of specific features or surfaces.

Collaborate on the inspection process

Generate detailed reports with numeric inspection

data, multiple views, annotated user-defined views,

notes and conclusions. Use Geomagic Review to share

inspection results with engineers, suppliers, partners,

contractors and customers at other physical locations.

and cameras. Import CAD models or use prior scans

for comparison. Define features to align models

using your method of choice (datums, features,

reference point system, 3-2-1 or best fit).

analysis very simple, while providing accurate

results. Specify graphical annotations to accelerate

correct go/no-go decisions. Facilitate problem

clarification with automatic annotation features.

selected regions. Analyze sheet metal features, generate

whisker plots of model cross-sections to assess springback,

cutting errors and perform wall-thickness analysis. Create

and evaluate GD&T callouts with full control over report

displays. Access industry-specific analytical aids including

airfoil and automotive analyses such as Gap & Flush.

to satisfy customer and regulatory requirements.

Create reports in several formats including HTML,

PDF and MS Word. Export CSV and Unicode data

for use in other applications such as SPC.

impellers. Geomagic Blade was developed as an extension to Geomagic Qualify based on unique requirements from leaders

in the turbine machinery industry such as Pratt & Whitney, Howmet, PCC Airfoils and Honeywell.

Geomagic CAD Importers allow direct, fast, and high quality import of CAD geometry (individual parts and assemblies) into

Geomagic Qualify, eliminating the need for intermediate neutral files such as IGES or STEP.